Industrial automation is evolving dramatically due to the advent of robotic arms. This has a significant impact on the manufacturing and production process. Robotic arms, referred to as Arm robots industrial, are today essential tools that offer unbeatable accuracy, safety, and efficiency across a range of industries. This article examines the multifaceted capabilities of robotic arms and explores their effect on modern business operations and the development of industrial automation in Australia.

Robotic arms, also known as robot arms, are a variety of mechanical devices created to replicate human arms’ functionality but with greater precision and endurance. Automated solutions have found extensive use in various industries like automotive manufacturing, electronics assembly, pharmaceuticals, and beyond, owing to their ability to perform complex, repetitive tasks with incredible precision. Robotic arms are able to be used in a variety of production settings. Their ability to be programmed enables the arms to be adapted to various operating requirements and provide an incredibly wide range of motion.

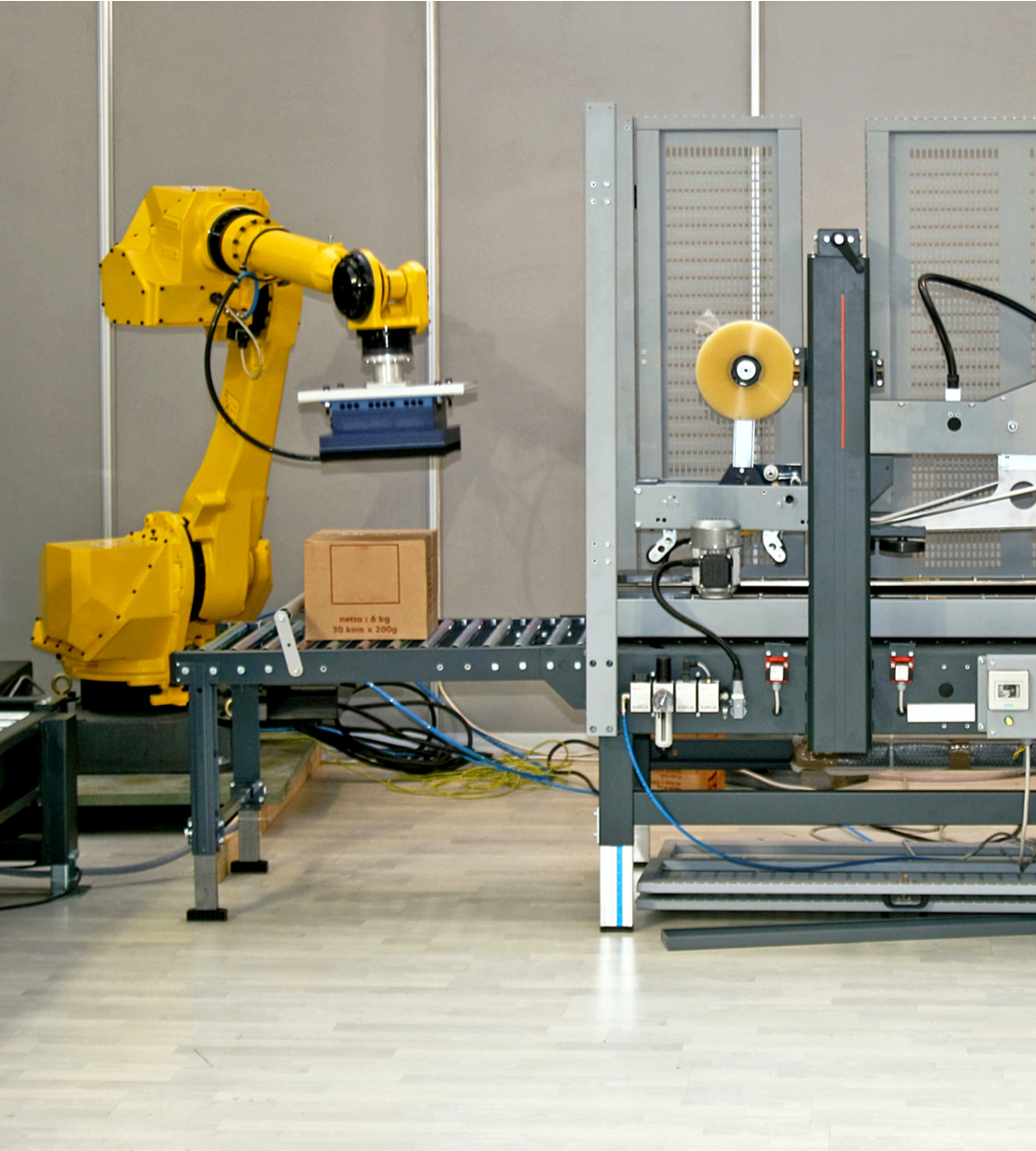

The Robotic arm companies, a cornerstone of modern automation, represents a sophisticated kinematic chain of joints that can move capable of rotating and performing linear displacements with extraordinary dexterity. It allows robots to move through complicated spatial configurations, and move objects with exact concentration on detail, all while ensuring optimal safety for humans. In the end, many companies have taken robotic arm as a vital asset to streamline production processes and increasing efficiency at unprecedented levels.

One of the primary characteristics of robotic arms is the use of end effectors. They are the functional equivalent of human hands. These end effectors, often designed to perform specific tasks, play a pivotal role in determining the nature of the applications that robotic arms can perform. From lifting and grabbing large loads, to creating intricate components, robotic hands with specially designed end effectors can allow robotic arms to execute a diverse array of tasks with unparalleled precision and reliability.

The integration of robotic arms into industrial automation has led to the beginning of a new era of productivity and innovation. With the help of robots, businesses are able to improve their manufacturing processes, decrease human error, and enhance overall quality of the product. The seamless coordination between robots and automated systems has brought about significant improvements in efficiency, which allows businesses to meet growing demands with incredible speed and precision. Click here Robotic Arm Companies

Robotic arms can have a transformative impact that extends beyond automation. They fundamentally change the way that industrial processes are conducted. The integration of industrial robots has improved manufacturing workflows and set the stage for entirely new production methodologies. The capability of robot arms to complete tasks in a hazardous environment or under difficult conditions has increased workplace safety and created new possibilities to manufacture operations.

The advancement of technology for robotic arms has also led to the development of end-effectors specifically designed to meet the needs of specific industries. These advanced end effects, which are equipped with the latest sensory and gripping technology, have widened the range of applications for robotic arms.

Companies in Australia have the unique opportunity to transform their competitiveness and operational capabilities by embracing the potential of robotic arms automation. Integration of robotic arms into industrial workflows is poised to spur sustained growth, boost overall productivity, and revolutionize the way that manufacturing is conducted. With a focus on efficiency and precision, robotic arms are poised to open new horizons in industrial automation, helping firms to achieve unprecedented levels of operational performance.

In conclusion, the integration of robotic or industrial arms is a significant advancement in industrial automation. Robotic arms with their unmatched precision, adaptability and safety features have redefined modern manufacturing. They give businesses a competitive advantage in a market that is becoming more competitive. The adoption of robotic arm technology will help businesses benefit from an increase in productivity, efficiency and innovation.